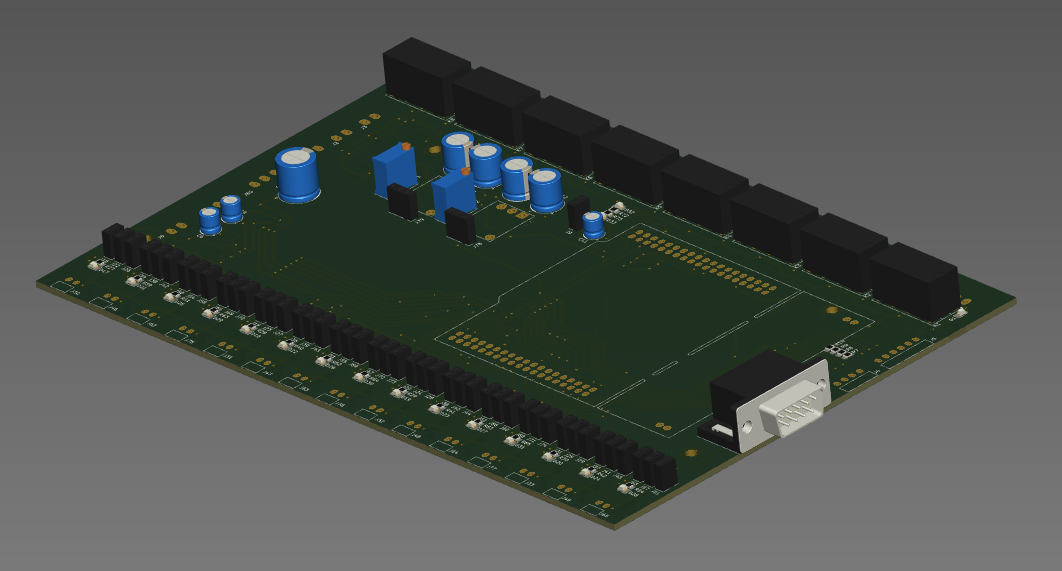

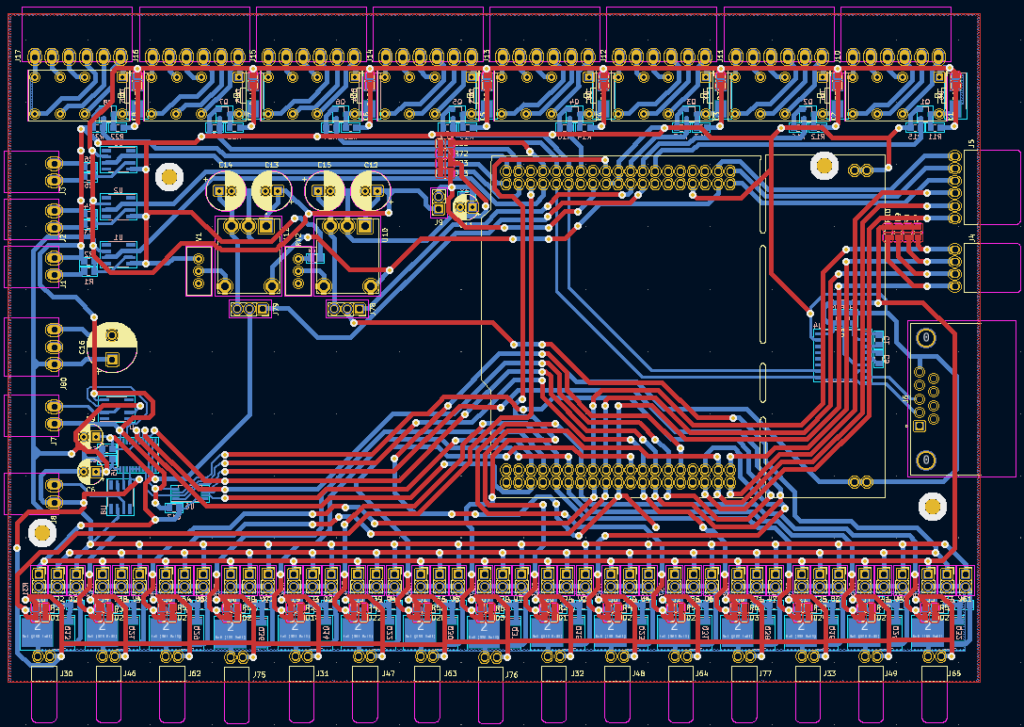

I/O Control Board reference project

Control Board with RS232 Communication

The control board serves as the central unit for managing various aspects of an industrial device, including pneumatics, the control panel, and indicator lights.

Key Aspects of the Control Board:

- Control Capabilities:

- The control board enables comprehensive management of the device’s pneumatic functions, allowing for efficient operation and monitoring. It also oversees the control panel and indicator lights, providing a user interface and visual feedback regarding the device’s status.

- Microcontroller:

- Control is executed by a NUCLEO F446RE microcontroller, which is part of the STM32 Cortex M4 family. This microcontroller is known for its performance and efficiency, providing the computational power required for controlling complex industrial processes.

- Power Supply:

- The system operates at a nominal voltage of 12V. This voltage is regulated down to 5V and 3.3V using two DC-DC converters, which are essential for powering the various actuators needed for the device’s operations. This multi-voltage support is critical for ensuring that all components receive the appropriate power levels.

- Output Management:

- High-power outputs are routed through Weidmüller BL 3.5 series connectors, which facilitate reliable connections for heavy-duty applications. These outputs are controlled by Omron G5V double-pole double-throw (DPDT) relays, known for their robustness and effectiveness in switching applications, ensuring the system can handle the demands of industrial environments.

- Input/Output Configuration:

- The board features 15 I/O pins that can be configured using jumpers. This flexibility allows for customizable connections based on specific application requirements. The I/O pins are equipped with Molex KK series connectors, which are reliable and widely used in industrial applications, ensuring secure connections.

- Sensor Integration:

- The system incorporates three analog inputs designed for receiving sensor signals. This allows for real-time monitoring of various parameters crucial for device operation. Additionally, it includes communication interfaces such as RS232, I2C, and SPI, enabling effective data exchange with other devices or control systems.

- Configuration Storage:

- Configuration settings received from a host device are stored in an SPI flash memory. This allows for persistent storage of settings, ensuring that the control board retains its configuration even after power cycling. The use of SPI flash provides a fast and reliable means for data storage and retrieval.

Conclusion:

This control board is a vital component for the efficient operation of an industrial device, integrating a robust microcontroller, multiple power supply options, flexible I/O configurations, and reliable output management. By effectively managing pneumatics and providing comprehensive connectivity for sensors and actuators, it ensures seamless operation in demanding industrial environments. The inclusion of communication interfaces further enhances its capabilities, making it suitable for a wide range of applications requiring precise control and monitoring.

Your vision, my creation!

I dare to dream and I won’t hesitate to bring it to life! I am here to make my boldest ideas a reality!